Late one night I found myself on a Pinterest board trying to understand the appeal of isomalt for candy-making and edible cake decorations.

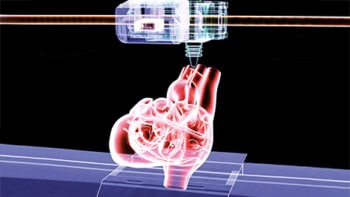

Why? A Twitter post announcing the latest research out of an interdisciplinary collaboration had caught my attention: complex networks of blood vessels can be 3D printed using isomalt, a sugar substitute usually used for making candies and decorative edible sculptures. Such work would open avenues for 3D printing personalized organs, reducing the human organ transplant shortage.

“Each year, thousands of patients die simply waiting for donor organs to become available,” says Jordan Miller, assistant professor at Rice University and the principal investigator leading the study. “These critical medical challenges motivate us every day to apply engineering principles to biology to build tissues and organs that can one day solve this challenge. Our own field of biomanufacturing, though still in its infancy, is rapidly gaining capabilities we couldn’t imagine a decade ago.”

Simply put, the researchers wanted to develop complicated vascular systems that can sustain engineered tissues and organs. And as it turns out, as the researchers explain in their Nature Biomedical Engineering paper, this is a really complex problem.

3D printing the lifeblood of tissues

The role of blood vessels is deceptively simple: to deliver oxygen and nutrients to tissues and carry away some waste. But blood vessels are an intricate network of incredibly extensive branching – they even grow in response to certain signals – all of which researchers must consider when 3D printing functioning tissues.

Conventional 3D printing methods aren’t suitable for replicating these delicate vascular webs. Take extrusion 3D printing, for example, in which structures are formed by melting strands of material that flow through a nozzle. Similar to the balsawood bridge you built in physics class, blood vessels created with this method will deform or collapse under their own weight unless supported by more 3D-printed material. Vessel networks that can be made with extrusion printing are therefore limited.

As if this wasn’t enough, 3D-printed blood vessels also need to keep engineered tissues alive. Any 3D-printed tissue will need to be chock-full of living cells to function, and vessels need to deliver oxygen and nutrients to the furthest reaches of engineered tissue. Because extrusion 3D printing cannot easily create dense networks of blood vessels, this task is also difficult.

Such engineering challenges required the researchers to rethink the way in which they 3D print tissues and blood vessels.

Printing with sugar

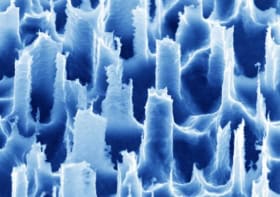

The researchers realized that they could apply a 3D printing technique already widely used for polymers and metals to build 3D-printed blood vessels that overcome these restrictions. The technique, called selective laser-sintering, uses a focused laser to melt and fuse small powder grains into pre-defined shapes. They found that these powdered grains could be sugars, and after much testing, they 3D printed a sugar template with extensive branching and unsupported overhangs using an isomalt mixture. The team collaborated with the Nervous System design studio to create the blood vessel network shape designs.

Next, they created a tissue by filling the space around the 3D-printed sugar template with a cell-infused gel. When this cell-infused gel solidified, the researchers dissolved the template using water and flushed it away, leaving empty channels primed to deliver oxygen and nutrients to cells.

It takes only five minutes to generate vascular tissues using this approach, compared with hours or days for conventional 3D printing techniques. This gives researchers time to send liquids containing oxygen and nutrients through the vessels and learn more about how cells function when supplied by these vessels.

Keeping cells alive with laser-welded sugar channels

“A major focus for this paper was to build spatial ‘maps’ of how cells function based on their position relative to the 3D-printed vascular network, to quantify how effective or efficient a particular vascular design is and better replicate what we see in the body,” says lead author Ian Kinstlinger, a graduate student in Miller’s lab at Rice University.

The researchers’ 3D printing technique, developed in collaboration with researchers at the University of Washington, Seattle, allowed them to control the engineered tissue environment, including tissue composition, cell types and blood flow, to better understand how cells retain their function over time. They demonstrated that their 3D-printed blood vessels could keep large and dense engineered liver tissues alive outside the body for at least a week.

What’s next for the tech

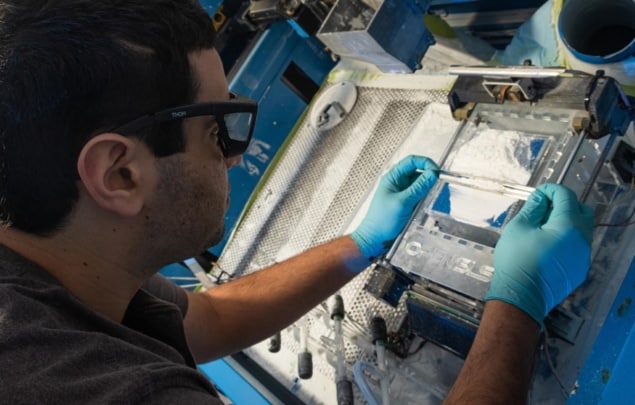

The researchers surmounted numerous feats of hardware and software engineering for this work to become reality.

“The sugar materials presented major fabrication challenges and required creative solutions, like developing a new kind of powder dispenser and laser control system,” says Kinstlinger. “There were virtually no blueprints for do-it-yourself, open-source selectively laser-sintered systems, and nobody had successfully shown selective laser-sintering with sugars.”

Currently, the researchers are working on a high-precision laser control system that will help them 3D print even smaller vessels (they can currently print vessels around 300 microns in size) so that vessels reach every piece of engineered tissue and keep cells alive.

There’s still much to learn from a biology perspective, including how various types of cells respond to environments engineered with this method.

And, armed by advances in biology research and their 3D printing technique, the researchers hope to extend the size and lifetime of engineered tissues and deploy the technology more widely. The 3D printing technique might also be useful to create medical imaging test devices like tissue phantoms, for example.

“Our long-term vision is an end to the donor organ shortage and replacement of damaged organs with new manufactured ones that are perfectly matched to each patient in need,” says Miller. “I am hopeful that efforts like ours will yield manufactured organs for human patients within my lifetime.”

As for me? I need to pay an online visit to a local bakery and partake in some sweet treats…for science’s sake.