Researchers from Washington State University (WSU) have developed a soy-infused 3D printed bone-like scaffold that’s capable of fighting off cancer cells.

In their research paper, WSU grad student Naboneeta Sarkar and Professor Susmita Bose, attempted to harness the health benefits of soy products to improve the post-operative care of cancer patients. By integrating soy-based chemical compounds into 3D bioprinted scaffolds, the duo were able to significantly reduce bone cancer cells in samples, while minimizing harmful inflammation.

In future, the novel 3D printing application could be leveraged as a more gentle treatment for the sufferers of osteosarcoma, a type of bone cancer that specifically affects young people.

“There is not much research in the area of natural medicinal compounds in biomedical devices,” said Bose. “Using these natural medicines, one can make a difference to human health with very minimal or no side effects, although composition control remains a critical issue.”

3D bioprinted scaffolds in the healthcare industry

Despite recent advances in modern medicine, the treatment of osteosarcoma and metastatic bone cancer has remained a challenge for medical staff around the world. The most common form of therapeutic treatment for osteosarcoma, is limb-salvaging surgery followed by chemotherapy, but this can cause large bone defects and inflammation.

As a result, an ideal post-surgical defect-repair treatment needs to be multifunctional, involving tissue regeneration, chemoprevention, and anti-inflammation. Bone Tissue Engineering (BTE) in particular, has increasingly been touted as an alternative to conventional resection, due to its compatibility with CAD software.

Leveraging CT scanning technology, it’s now possible to create a CAD model of a bone defect, and summarily 3D print precise patient-specific prosthetics. A number of bioprinting researchers are now building on the idea of printed bone grafts, by creating porous scaffolds from various types of stem cells. The in vivo nature of the fabricated tissues lends them excellent biocompatibility, and they have been extensively used within BTE.

Given that implanted scaffolds are integrated into the host’s organic tissues, they can also effectively be used as local drug delivery systems. Taking advantage of this unique bio-link, the researchers hypothesized that adding soybean extracts to bioprinted scaffolds would enable the patient to reap the seed’s well-documented health benefits.

The research team’s bean-based scaffold

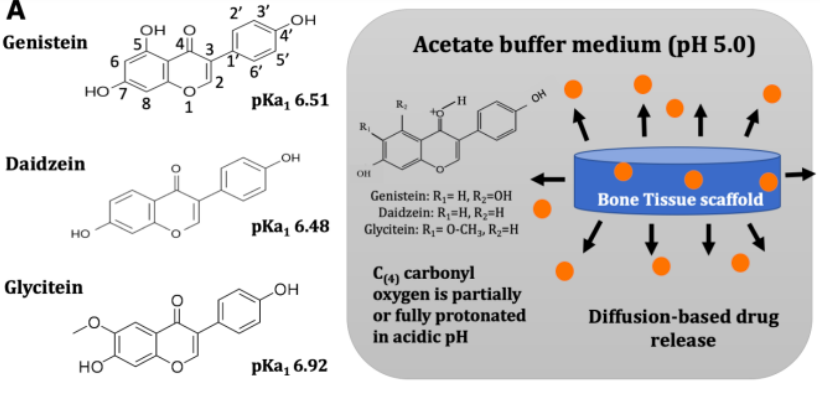

In order to create their porous scaffolds, the research duo used a binder jetting technique to 3D print a mixture of cancer-resistant soy isoflavones and fetal stem cells. The isoflavones, containing genistein, daidzein, and glycitein, were mixed in a 5:4:1 ratio, in order to match the chemical proportions found in natural soybeans.

Once the thirty hour scaffold fabrication process was complete, the tissue was seeded with the drug mixture at pH 7.4 and pH 5.0, to imitate that of patients’ internals after bone graft surgery. Fetal Bovine Serum (FBS) cells were later added to the scaffold, as a substitute for in vitro cells, and the concoction was mixed together at 37oC in an orbital shaker.

The team tracked their mixture’s reaction over eleven days, and although all three isoflavones were consistently released, different mixtures of the chemicals were found to induce varying levels of immune reaction. One particular soybean mixture proved efficient enough to cause a 90 percent reduction in bone cancer cell viability, while two others merely improved the growth of healthy bone cells.

To evaluate the in vivo surgical applications of their bioprinted scaffold, the researchers implanted the cells into the bone defect site of an anaesthetised lab rat. The soy compound demonstrably reduced inflammation, a key requirement of BTE treatment, and an important way of preserving future bone health.

Given that their soy-infused scaffold had shown considerable proficiency in combating cancer cells, the researchers concluded that their approach had been successful. Although Bose conceded that further testing was needed to fully validate their findings, she said that the study had proven the benefits of integrating natural compounds into biomedical devices.

“These results advance our understanding in providing therapeutic approaches by using synthetic bone grafts as a drug delivery vehicle,” summarized Bose.

Optimizing the 3D bioprinted scaffold

3D printed scaffolds are one of the hottest topics in regenerative medicine right now, and researchers have deployed the fabricated tissues within a wide variety of applications in recent years.

A research team from the Delft University of Technology have developed a novel method of producing 3D printed biodegradable magnesium scaffolds. The solvent-cast tissues could have promising applications in the regeneration of critical-sized bone defects.

Scientists from the UK’s Animal Health Trust (AHT) and the University of East Anglia (UEA) meanwhile, are leveraging 3D printed scaffolds to support bone regeneration in horses. Using the PLA-based tissues, the team were able to turn stem cells into bone forming cells called osteoblasts, which can be used for treating bone fractures.

Researchers based at Rice University and the University of Maryland (UMD) have outlined plans to use additive manufactured scaffolds to fabricate artificial bone tissues. The team’s prototype material was found to mimic the behaviours of cartilage, and proved to be mechanically comparable to natural bone.

The researchers’ findings are detailed in their paper titled “Controlled Release of Soy Isoflavones from 3D Printed Bone Scaffolds for Bone Tissue Engineering,” which was published in the Acta BioMaterialia journal.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a series of soy-based products, the kind that inspired the WSU team to utilize soybeans within their research. Image via WSU.