Researchers convert old tires into graphene to strengthen concrete

Researchers from Rice University have optimized a process to convert waste rubber from old tires into graphene. That graphene can then be used to strengthen concrete. Research chemist James Tour says that the environmental benefits of adding graphene to the concrete are clear.

Concrete is one of the most produced materials in the world, and the production of concrete makes much as nine percent of the world's carbon dioxide emissions. Tour says if we're able to use less concrete in our roads, buildings, and bridges, we can eliminate some of the carbon dioxide from the start. Portland cement already uses recycled tire waste as a component, but graphene has been proven to strengthen cementitious materials, including concrete, at the molecular level.

Most of the 800 million tires discarded annually are burned for fuel or ground for other applications, with 16 percent of old tires winding up in landfills. The ability to reclaim even a fraction of those landfill tires as graphene will keep millions of tires from reaching landfills. Tour and his colleagues have unveiled a "flash" process used in 2020 to convert food waste, plastic, and other carbon sources by exposing them to a jolt of electricity, removing everything but carbon atoms from the sample.

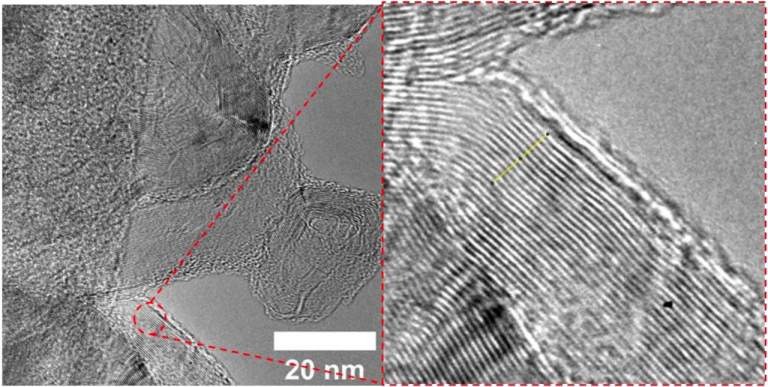

The atoms reassemble into valuable turbostratic graphene with misaligned layers that are more soluble than graphene produced via exfoliation from graphite. Being more soluble makes graphene easier to use in composite materials. Researchers say that rubber was more challenging than food or plastic to convert into graphene, but the process was optimized using commercial pyrolyzed waste rubber from tires.

Tire-derived carbon black, a blend of shredded rubber tires, and commercial carbon black can be flashed into graphene. Since turbostratic graphene is soluble, it's easily added to cement to create more environmentally friendly concrete. About 70 percent of the tire-derived carbon black converted to graphene in testing.