Abstract

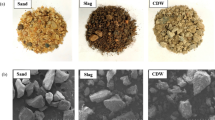

Mine tailings are stored in tailings storage facilities (TSF), normally in the form of tailings dams. High-stacked tailings dams (HTD) are failure-prone for several reasons, such as overtopping, seepage failure, and strength deterioration. The investigation of compressibility and permeability of tailings material with different particle sizes under high pressure is essential for safety stability. By self-developed high-pressure consolidation permeability apparatus (HCPA), the laboratory conjoined consolidation permeability tests are carried out on tailings with different particle sizes at the maximum consolidation pressure (σ’v) of 5 MPa. For compressibility of tailings in the high-pressure stage (σ’v > 2 MPa), the void ratio e of tailings with different particle sizes has a new linear relationship with σ’v. Coarse-grained tailings have a “secondary- compression-like property” due to particle breakage under high pressure. The hydraulic conductivity of tailings under high pressure presents a piecewise linear k-σ’v relationship. With the decrease in particle size and the increase of σ’v, the seepage pattern of tailings changes from channel seepage to micropore seepage. σ’v = 2 MPa is regarded as the critical value for high-pressure compression of tailing, and the corresponding microscopic critical value of the average particle spacing is 1.2–1.8 nm. This research explored useful information on the compressibility and permeability of tailings with different particle sizes under high pressure that can provide a reference for improving the stabilization of HTD.

Similar content being viewed by others

References

American Society for Testing and Materials (ASTM) ASTM D5550 (2014) Standard Test Method for Specific Gravity of Soil Solids by Gas Pycnometer. ASTM D698, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort

Amin C, Mahdi K, Hamid N (2018) Liquefaction resistance of fibre reinforced low-plasticity silt. Soil Dyn Earthq Eng 104:372–377. https://doi.org/10.1016/j.soildyn.2017.11.004

Anandarajah A (1997) Influence of particle orientation on one-dimensional compression of montmorillonite. J Colloid Interf Sci 194(1):44–52. https://doi.org/10.1006/jcis.1997.5068

Azam S, Li Q (2010) Tailings dam failures: a review of the last one hundred years. Geotech News 28(4):50–53

Bellendir E, Filippova E, Buryakov O, Vakulenko A (2019) Maintenance of safety and reliability of high tailings dams in cold regions of Russia during the design phase. Sustainable and Safe Dams around the World. https://doi.org/10.1201/9780429319778-312

Bolt GH (1956) Physico-chemical analysis of the compressibility of pure clays. Géotech 6(2):86–93

Bourg IC, Steefel CI (2012) Molecular dynamics simulations of water structure and diffusion in silica nanopores. J Phys Chem 116(21):11556–11564. https://doi.org/10.1021/jp301299a

Burland JB (1990) On the compressibility and shear strength of natural clays. Géotech 40(3):329–378

Chai JC, Miura N, Zhu HH, Yudhbir (2004) Compression and consolidation characteristics of structured natural clay. Can Geotech J 41(6):1250–1258. https://doi.org/10.1139/t04-056

Chandler RJ (1985) Tosatti G (1995) The Stava tailings dams failure, Italy. International Journal of Rock Mechanics and Mining Science & Geomechanics Abstracts 33(1):30–35. https://doi.org/10.1201/9780429319778-312

David W, Iii C, Asce F (1962) Goodbye, Hazen; Hello. Kozeny-Carman J Geotech Geoenviron Eng 40(120):260–261

Djéran I, Tessier D, Grunberger D (1998) Evolution of microstructures and of macroscopic properties of some clays during experimental compaction. Marine Petro Geol 15(2):109–128. https://doi.org/10.1016/S0264-8172(97)00062-7

Fourie A, Verdugo R, Bjelkevik A, Torres LA, Znidarcic D (2022) 20ICSMGE State of the Art - Tailings. In Md. M. Rahman & M. Jaksa (Eds.), 20th International Conference on Soil Mechanics and Geotechnical Engineering - State of the Art and Invited Lectures (pp. 121–183).

GB50863 (2013) Code for design of tailings facilities.

Guo ZS (2010) Stability analysis of high-stacked tailings dam and research on key reinforcement technology. Xi'an University of Technology

Horpibulsuk S, Yangsukkaseam N, Chinkulkijniwat A, Yan JD (2011) Compressibility and penetration of Bangkok clay compared with kaolinite and bentonite. Appl Clay Sci 52(1–2):150–159

Hu L, Wu H, Zhang P, Wen Q (2017a) Geotechnical properties of mine tailings. J Mater Civ Eng 29(2), 04016220. https://doi.org/10.1061/%28ASCE%29MT.1943-5533.0001736

Hu X, Oommen T, Lu Z, Wang T, Kim JW (2017b) Consolidation settlement of Salt Lake County tailings impoundment revealed by time-series InSAR observations from multiple radar satellites. Remote Sens Environ 202:199–209. https://doi.org/10.1016/j.rse.2017.05.023

Huang WX (1983) Engineering properties of soil. Water Conservancy and Electric Power Press.

Ichikawa Y, Kawamura K, Nakano M (2001) Seepage and consolidation of bentonite saturated with pure-or salt-water by the method of unified molecular dynamics and homogenization analysis. Eng Geol 60(1–4):127–138. https://doi.org/10.1016/S0013-7952(00)00095-8

Islam S, Shang JQ (2019) Coagulation enhanced electrokinetic settling of mature fine oil sands tailings. Int J Min Sci Technol 29(2):199–208. https://doi.org/10.1016/j.ijmst.2018.04.012

Kumar GV, Wood DM (1999) Fall cone and compression tests on clay-gravel mixtures. Geotech 49(6):727–739. https://doi.org/10.1680/geot.1999.49.6.727

Küpper AM (1991) Design of hydraulic fill

Leroueil S, Kabbaj M, Tavenas F, Bouchard R (1985) Stress- strain-strain rate relation for the compressibility of sensitive natural clays. Géotech 35(2):159–180. https://doi.org/10.1680/geot.1985.35.2.159

Li W, Coop MR, Senetakis K, Schnaid F (2018) The mechanics of a silt-sized gold tailing. Eng Geology 241:97–108. https://doi.org/10.1016/j.enggeo.2018.05.014

Liu HM, Yang CH, Zhang C, Mao HJ, Cao J (2012) Study of characteristics of power function Mohr strength criterion for tailings material under high pressures. Rock Soil Mech. 33(7), 1986–1992. https://doi.org/10.16285/j.rsm.2012.07.037

Ma CK, Zhang C, Chen QL, Pan ZK, Li XT (2021) On the effect of void ratio and particle breakage on saturated hydraulic conductivity of tailing materials. Geomechan Eng. 25(2), 159–170. https://doi.org/10.12989/gae.2021.25.2.159

Maio CD, Santoli L, Schiavone P (2004) Volume change behaviour of clays: the influence of mineral composition, pore fluid composition and stress state. Mech Mater 36:435–451. https://doi.org/10.1016/S0167-6636(03)00070-X

Marcial D, Delage P, Cui YJ (2002) On the high stress compression of bentonites. Can Geotech J 39(4):812–820. https://doi.org/10.1139/t02-019

Payan M, Khoshghalb A, Senetakis K, Khalili N (2016) Small-strain stiffness of sand subjected to stress anisotropy. Soil Dyn Earthq Eng 88:143–151. https://doi.org/10.1016/j.soildyn.2016.06.004

Rhaem HB, Pons CH, Tessier D (1987) Factors affecting the microstructure of smectites. Role of cations and history of applied stresses. In Proceedings of the International Clay Conference, Denver. The Clay Mineral Society. 292–297

Schiffman RL, Ladd CC, Chen ATF (1966) The secondary consolidation of clay//Rheology and Soil Mechanics/Rhéologie et Mécanique des Sols. Springer, Berlin, Heidelberg 1966:273–330

Shang XY, Zhou GQ, Kuang LF, Cai W (2015) Compressibility of deep clay in East China subjected to a wide range of consolidation stresses. Can Geotech J 52(2):244–250. https://doi.org/10.1139/cgj-2014-0129

Solans D, Kontoe S, Zdravkovik L (2019) Monotonic and cyclic response of tailings sands. In 2019 SECED Conference. Earthquake risk and engineering towards a resilient world. Greenwich, London

Tripathy S, Schanz T (2007) Compressibility behaviour of clays at large pressures. Can Geotech J 44(3):355–362. https://doi.org/10.1139/t06-123

Valenzuela L (2016) Design, construction, operation and the effect of fines content and penetration on the seismic performance of tailings sand dams in Chile. Obras y Proyectos 19:6–22

Wang ZC, Qiao LP, Li SC (2011) Energy analysis of particle breaking process. Chinese Society of Hydropower Engineering

Xia LQ, Li L (2015) Safe operation practice of Wanniangou tailings reservoir in Baima iron mine. Modern Mining. (9), 168–169+199.

Yang S, Liu W (2020) Application of image-pro plus in the shear strength and micro-structure of solidified soil mixed with fly ash. Multimed Tools Appl 79:10065–10075. https://doi.org/10.1007/s11042-019-07804-w

Yin GZ, Wang WS, Wei ZA, Cao GS, Zhang QG, Jing XF (2018) Permanent deformation and stability analysis of high-stack tailings dam under earthquake. Soil Mech. 39(10): 3717–3726. https://doi.org/10.16285/j.rsm.2017.0199

Zhang C, Chen Q, Pan Z, Ma C (2019) Mechanical behavior and particle breakage of tailings under high confining pressure. Eng Geol. 265, 105419. https://doi.org/10.1016/j.enggeo.2019.105419

Funding

The research was supported by the National Key Research and Development Program of China (NO. 2017YFC0804601), National Natural Science Foundation of China (No. 51741410), and Natural Science Foundation for Innovation Group of Hubei Province, China (No. 2016CFA014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, C., Li, R., Zhang, C. et al. A study on compressibility and permeability of tailings with different particle sizes under high pressure. Bull Eng Geol Environ 82, 106 (2023). https://doi.org/10.1007/s10064-023-03117-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-023-03117-3